- Hign-concerned Chemical: None

- Brand Name: NoEnName_Null

- Origin: Mainland China

- Certification: CE

- Product Type: Toilet Paper Rewinding Machine

- processing type: Paper Slitting and Rewinding Machine

- place of origin: Henan, China

- brand name: YG

- voltage: 220V/380V

- power(w): 7.5kw

- dimension(l*w*h): 6300*3650*1800mm

- warranty: 1 Year

- production capacity: 180-200 m/min

- machinery test report: Provided

- video outgoing-inspection: Provided

- core components: PLC, Gear, motor, Bearing, Gearbox

- Weight (KG): 1000

- Product Name: Toilet tissue roll making machine

- Raw material: Jumbo Roll Toilet Tissue Paper

- Output paper: Small toilet paper roll, kitchen towel, hand towel

- Machine capacity: 2-5 tons per day

- Embossing roller: Steel to rubber, steel to wool, steel to steel

- Control system: PLC Control,Variable Frequency Speed Control,Touch Screen Operation

- Application: Paper Industry

- Production line: Toilet paper cutting and packing machine

- After-sales Service Provided: Online support

- Certification: CE, ISO9001

Production Description

Toilet paper converting machine is widely used in toilet paper shaft, non-woven fabric, air-laid paper cutting rewinding, slitting width, layer number can be adjusted according to need, quick speed, stable running, simple operation, is the paper mill or cutting and ideal facilities for the production of paper products plant. this rewinding machine can be with embossing roller and paper tube feeder. we are factory for toilet paper rewinding machine, rewinder slitter machine, toilet paper converting machine,toilet paper roll making machine, toilet paper roll cutting machine, toilet paper roll packing machine, napkin paper machine,tissue paper machine and so on.

Technical Parameters

|

Machine Model

|

1092/1575/1880/2100/2400

|

|

Paper Width(mm)

|

1092mm/1575mm/1880mm/2100mm/2400mm

|

|

Paper Diameter(mm)

|

φ1200mm(Please Specify)

|

|

Paper Core Inner Diameter

|

φ76mm(Please Specify)

|

|

Product Diameter

|

φ40mm-200mm

|

|

Paper Backing

|

1-4layer,general chain feed or continuously variable transmission feed paper

|

|

Punch

|

2-4 Knife,Spiral Cutter Line

|

|

Hole Pitch

|

Positioning of Belt and Chain Wheel

|

|

Control System

|

PLC Control,Variable Frequency Speed Control,Touch Screen Operation

|

|

Product Range

|

Core Paper,Non Core Roll Paper

|

|

Drop Tube

|

Manual,Automatic(Optional)

|

|

Non core roll paper

|

automtic core pulling

|

|

Production Speed

|

150-280m/min

|

|

Spray,Cutting and Rewinding

|

Automtic

|

|

Finished product launch

|

Automtic

|

|

Point Moving Mode

|

Before and After the Point Moving

|

|

Power Configuration

|

380V50HZ

|

|

Required air pressure

|

0.5Mps(The Self)

|

|

Embossing

|

Single Embossing,Double Embossing(Steel Roller to Wool Roller,Steel Roller)Optional

|

|

Blank Holder

|

Airbag Control,Cylinder Control,Steel to Steel Structure

|

|

Outline Dimension

|

6200mm-7500mm*2600mm-3200mm*1750mm

|

|

Machine Weight

|

2900KG-3800KG

|

Production Process

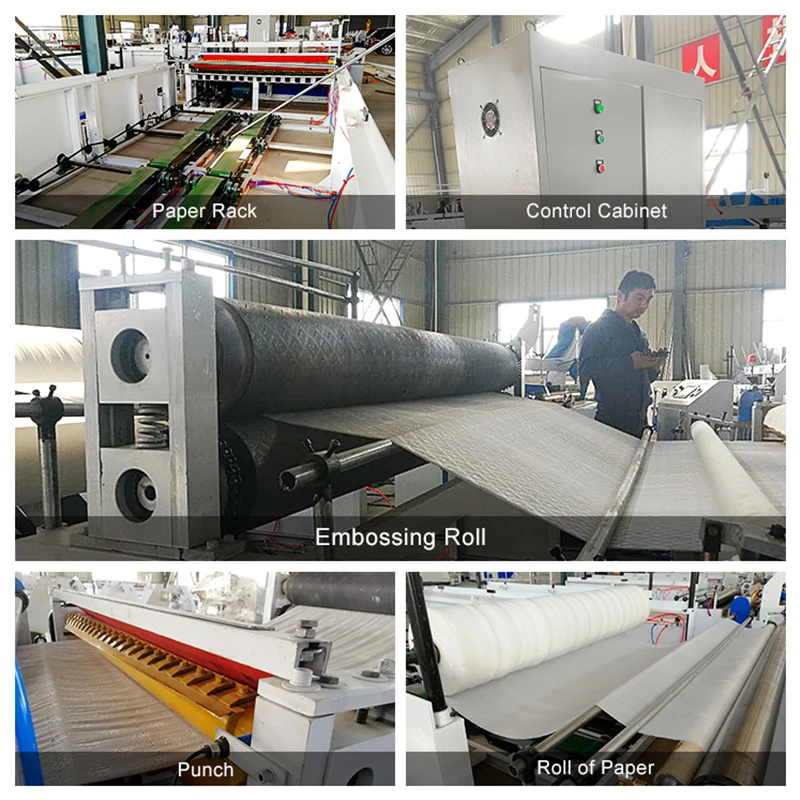

Detailed Images

Toilet paper converting machine main include toilet paper jumbo roll loading system, pneumatic control, embossing part, perforating part, lamination part, paper tube feeder part and so on.we are factory for toilet paper rewinding machine, rewinder slitter machine, toilet paper converting machine,toilet paper roll making machine, toilet paper roll cutting machine, toilet paper roll packing machine, napkin paper machine,tissue paper machine and so on.

Recommend Products

Packaging &Delivery

Reviews

There are no reviews yet.